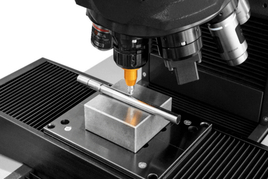

QATM is a pioneer in the field of hardness testing, offering top-quality universal hardness testing models in the well-known Brinell, Knoop, Rockwell, and Vickers scales. With a wide range of loads and different design structures, QATM can meet every possible hardness testing application, ensuring precision, repeatability, and unparalleled reliability. Holding a leading position across Europe in high-end hardness testing models, the company can proudly claim to produce the best and highest-quality hardness testing instruments.

QNESS 200 CS

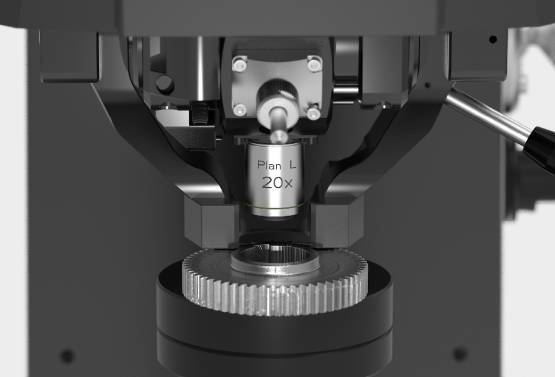

The QNESS 200CS model is a hardness tester that combines speed, precision, and affordability. It was designed with maximum performance in mind, requiring minimal effort from the user. The solid structure of the hardness tester, featuring a fixed head and a movable axis, enhances its robustness (Compactness), while its 5-position head provides exceptional speed. These two characteristics give the model its CS (Compactness and Speed) designation. With a testing height of up to 250mm, the QNESS 200 is ideally suited for small to medium-sized samples.

During the development of the Qness 200 units, particular attention was paid to the following things: Maximum performance with minimum effort.

QNESS 200CSA+

Highly automated, precise and reliable hardness tester.

During the development of the Qness 200 units, particular attention was paid to the following things: Maximum performance with minimum effort.

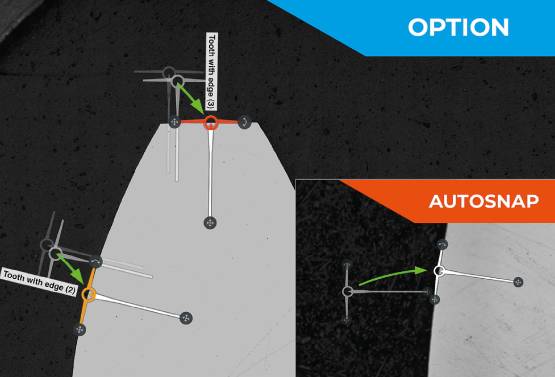

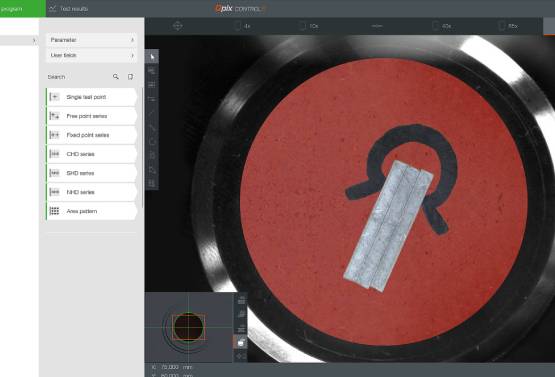

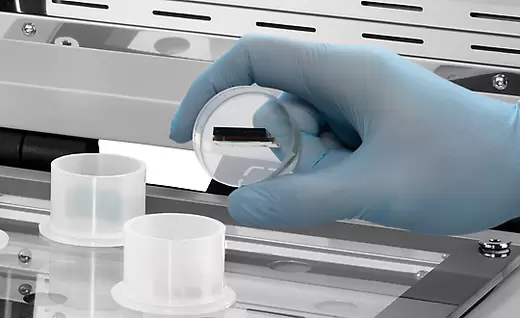

A fully automatic XY slide will guarantee high precision hardness testing. It is ideal for fully automatic repeated tests and progression tests. Its optical system with color camera provides reproducible and reliable results every time.

Operation via an external PC system is carried out based on the user-friendly Qpix Control 2 hardness testing software, providing benefits such as automatic height adjustment, contactless exploration, or CAD compatibility.

QNESS 250 / 750 / 3000 CS/C EVO

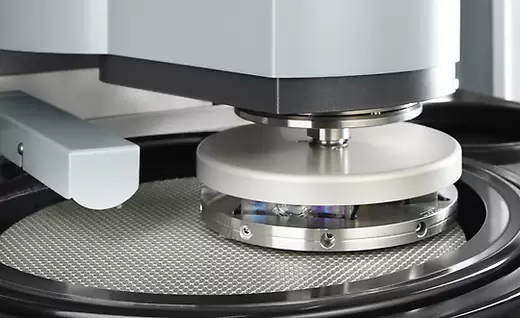

The new Brinell / Knoop / Rockwell / Vickers hardness tester series EVO by QATM combines extremely short cycle times with maximum precision.

The characteristic "C" shaped machine frame gives the CS and C versions of the Qness 250/750/3000 EVO series their name.

The proven concept with fixed test head and up/down moving spindle has been standard in hardness testing for many decades and is ideally suited for small test pieces - as model "C" for component heights up to a maximum of 395 mm and as an even more compact model "CS" with 175 mm maximum test height.

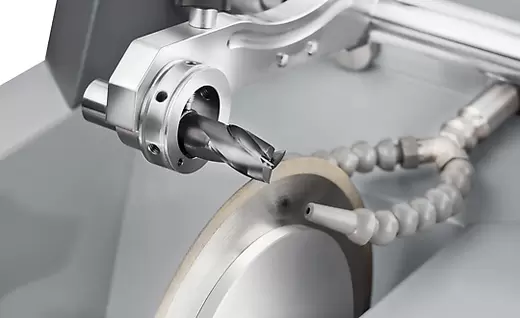

QNESS 250 / 750 / 3000 M EVO

The QATM QNESS 250 / 750 / 3000 M EVO hardness testing models (M series) provide a stable base (fixed component support) and extra space for sample measurements (extra-large test table area), making them perfectly suited for hardness testing of large specimens. The test head is manually moved using a special handwheel located at the front of the hardness tester. The test head bearing is designed to offer exceptionally smooth movement, allowing operation with minimal user effort. The maximum testing height is 510mm.

QNESS 250 / QNESS 750 / QNESS 3000 E EVO

A hardness tester for all purposes: no matter if operated in a laboratory or in a rough production environment. The fixed component support and extra-large test table area allow hardness testing of even the largest components. In the "E" version, the test head is conveniently and dynamically controlled by the integrated asynchronous motor. Test pieces of virtually any size, weighing up to 3500 kg, are securely clamped in the device. The maximum test height is 510 mm.