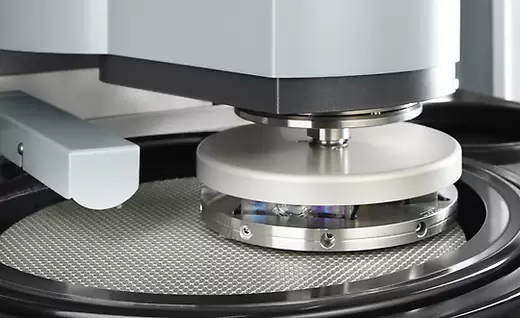

Hardness and scratch testers analyze adhesion in scratches, hardness, modulus, and scratch resistance. Such measurements provide analysis on the nano, micro, and macro scales. Specifically, hardness testers offer automatic load-displacement curves, hardness (both traditional and instrumented), elastic modulus, creep, and many other calculations. They feature easily interchangeable indenter heads that cover multiple loads ranging from mN to 40 N, and provide unmatched performance with patented capacitive sensor technology. Additionally, various diamond indenter tips are available, such as Berkovich, Vickers, Spherical, Cube Corner, Knoop, and more, while there is always the option for standard Vickers hardness or other traditional hardness scales. Scratch testing, on the other hand, provides characterization of coating adhesion, scratch resistance, scratch hardness, and much more.

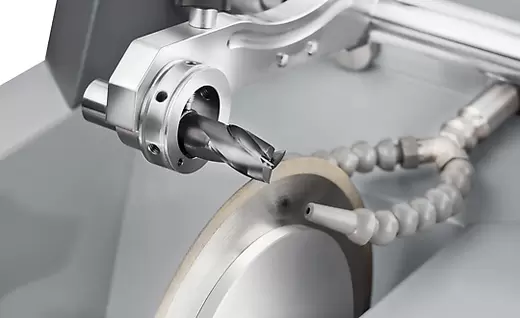

In addition, the in-line integrated profilometer provides 3D stitched images. These images characterize the coating failures. Advanced capacitive sensors measure penetration depth. They provide measurements with the resolution needed to differentiate coatings with similar properties. For this reason, Rtec-Instruments has developed a simple method to test coating adhesion for various applications. Examples are wear resistance on cutting tools, the film thickness on transparent lenses, or the hardness of automotive coatings.

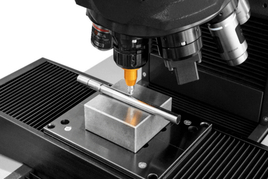

Indentation and 3D Scratch Tester SMT-5000

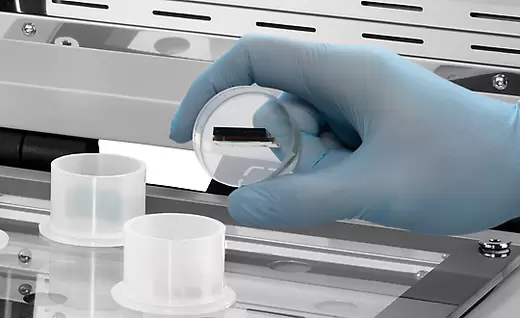

Indentation and 3D Scratch Tester SMT-5000 is a compact surface materials tester with a patented integrated 3D profilometer. The SMT-5000 is an all-in-one modular platform that measures hardness (instrumented indentation), scratch adhesion & cohesion,scratch hardness, film thickness, and multi-pass wear at nano and micro scale. Each indentation and scratch test is precise, ISO, and ASTM compliant.

The Surface Mechanical Tester SMT-5000 is a versatile instrument. It merges the ability to measure mechanical properties, such as hardness, modulus, scratch adhesion, film thickness, in addition to surface roughness and many others. All this power is consolidated in one single platform. To that end, the IST module provides both indentation and scratch. Combining piezo actuation and capacitive sensing technologies, the IST brings the highest precision measurements from nano to micro ranges.

Besides the IST module, the SMT-5000 incorporates spectral reflectance film thickness with 3D profilometry and environmental modules. All these capacities cater to demanding engineers and researchers in many fields.