Tribometers study wear, friction, and lubrication on interacting surfaces. When two surfaces rub together, they create friction. Over time, these two surfaces create wear. Therefore, the applications of tribometers is universal and their analysis impact our everyday life. Tribometer analysis and their friction technology can be seen in daily life. Simple examples are car brakes and their longevity. Or a phone’s touch screen and its durability. Rtec Instruments manufactures tribometers and provides the failure analysis needed to improve products and mechanical systems.

Because friction is everywhere, tribometers play a major role in improving the efficiency of industrial products and energy conservation. Therefore, Rtec tribometer applications are found in a wide range of industries. Such as aerospace, automotive, biomaterials, hard coatings, optics and glass, polymer, semiconductors, and so much more.

Rtec Instruments’ Universal Tribometer contains versatility and modularity that provides several tribological and mechanical testing solutions for various industries.

Furthermore Rtec Instruments provides tribometers that characterize friction, wear, adhesion, fatigue, and many other mechanical surface properties—offering advanced, precise, and customizable tribology testing equipment.

Multi Function Tribometer MFT-2000

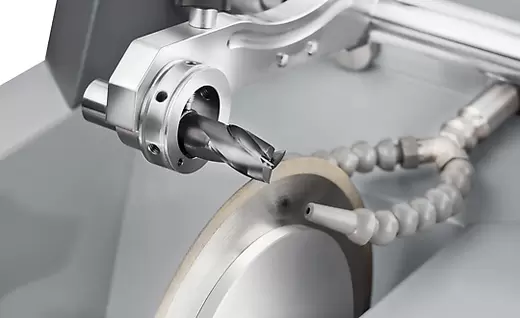

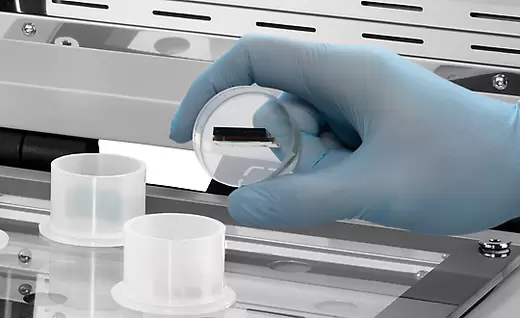

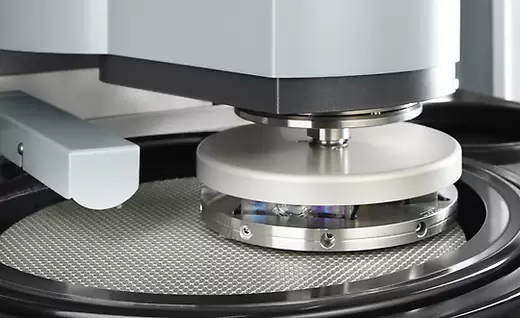

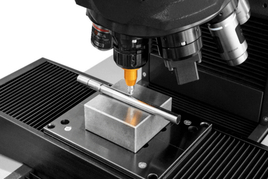

MFT-2000 Multi Function Tribometer is a bench-top tribometer for tribology, wear, and scratch tests. With a patented integrated 3D profilometer and real-time force control, the MFT-2000 is easy to use. Wide force and environmental conditions are available. Multi Function Tribometer MFT-2000 is actually a versatile and technologically advanced bench top tribometer for essential mechanical, scratch, and tribological characterization. An open platform architecture design for multiple configurations and ease of use. Fully automated test programs and advanced controllers allow for high repeatability and precision measurements. The servo control load patented multi-dimension force sensors and XY stage allows the MFT-2000 tribometer to run several tests covering scratch, tribology, wear, mechanical tests, and profilometry on the same platform.

Main Features (Depends on configuration)

Multi Function Tribometer MFT-5000

Multi Function Tribometer MFT-5000 is a versatile tribometer with a patented integrated 3D profilometer. Its large working area and most comprehensive test conditions represent a highly customizable instrument with a full list of environmental chambers and options. The Multi Function tribometer MFT-5000 is globally regarded as the most versatile and advanced. With patented force sensors, the MFT-5000 reaches super high speeds. As well as an extensive environmental control range, the model provides modularity. No other commercially existing tribometer performs such speeds and environments on one platform. In addition, the tribometer contains a patented integrated 3D profilometer. This allows surface analysis of change vs. time. As a result, the MFT-5000 is perfect for comprehensive analysis of coefficient of friction, wear, hardness, adhesion, and more.