In metallography, mounting is typically the second process step after sectioning. Mounting encapsulates the sampled material with a plastic shell and prepares the sample for the following metallographic grinding and polishing step. In many cases it leads to a simplified sample preparation and thus to better results. Primarily, mounting is divided into two main categories: Hot mounting and Cold mounting.

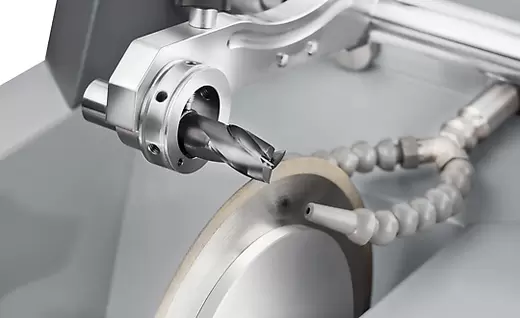

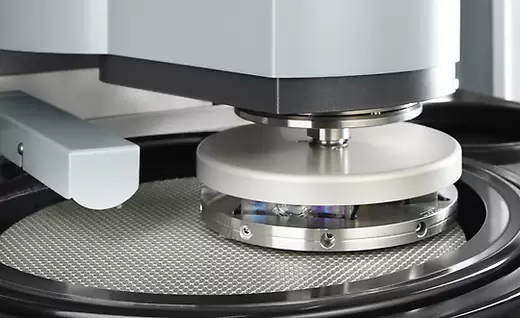

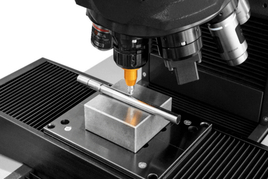

High sample throughput can only be managed by employing technology. QATM offers robust hot mounting presses, which offer different pressure- and temperature modes for the generation of almost gapless mounted samples. A sufficient selection of cylindric and rectangular moulds is available for the users. Intuitive software and good ergonomics are further defining properties of the offered products.

QATM, however, offers also devices for mounting samples under UV irradiation. This enables the fast generation of transparent, mounted samples for standard applications. These devices offer long-lasting LED technology.

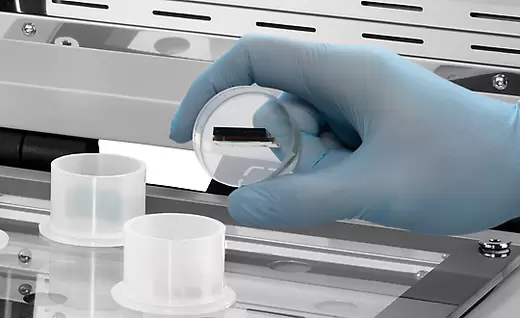

Finally traditional cold mounting devices of metallographic samples under vacuum are available (Infiltration Unit) and Pressure equipment cold mounting devices for bubble free hardening of methyl methacrylates (acrylic resins).

There are several mounting consumables available both for hot and cold mounting and specifically cold and hot mounting resins, mounting moulds, anti-stick liquids and powders, plastic and metal fixation clips and others.