10, Agion Anargiron Str.

Marousi Attica, 151 24

Greece

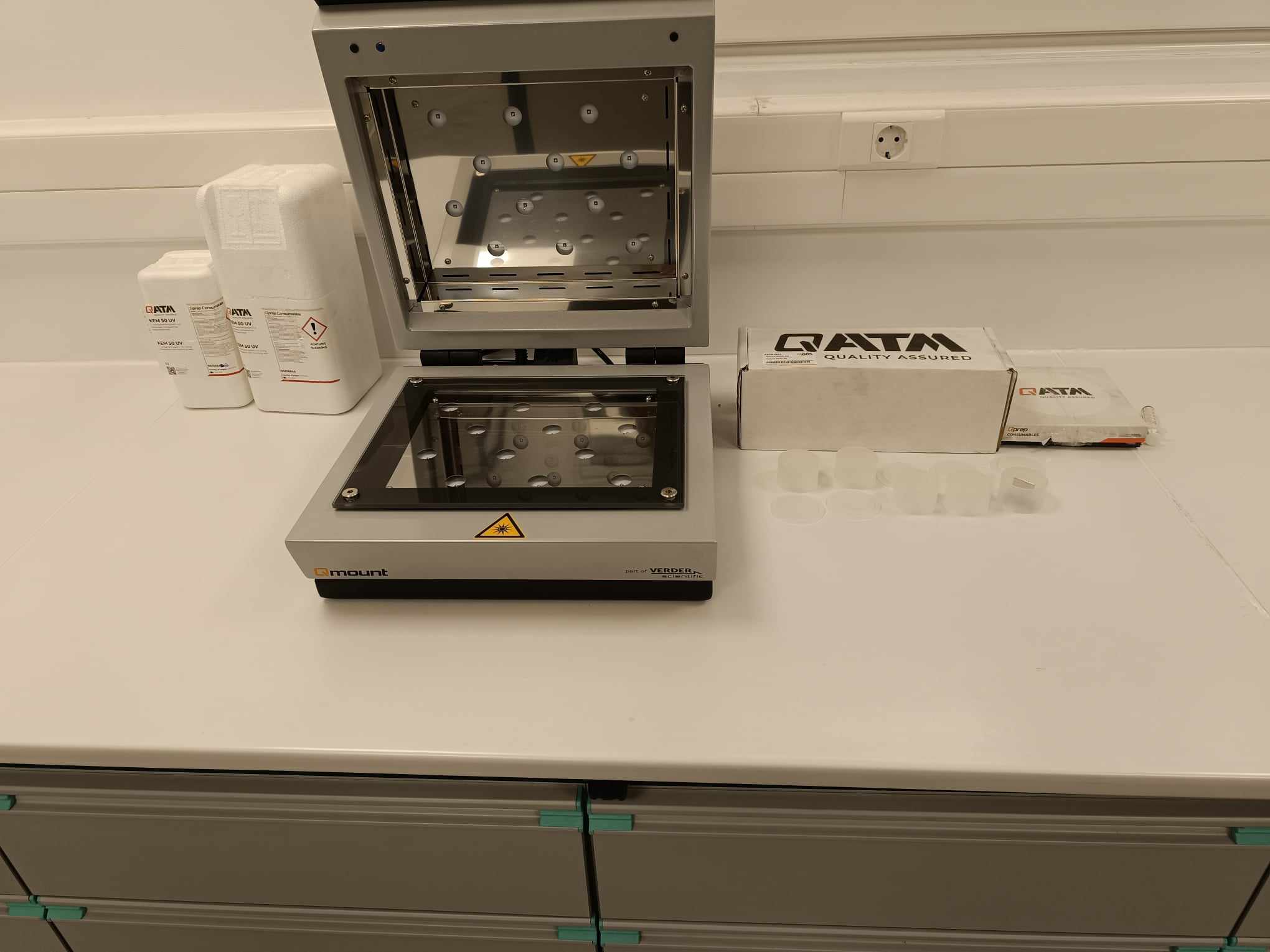

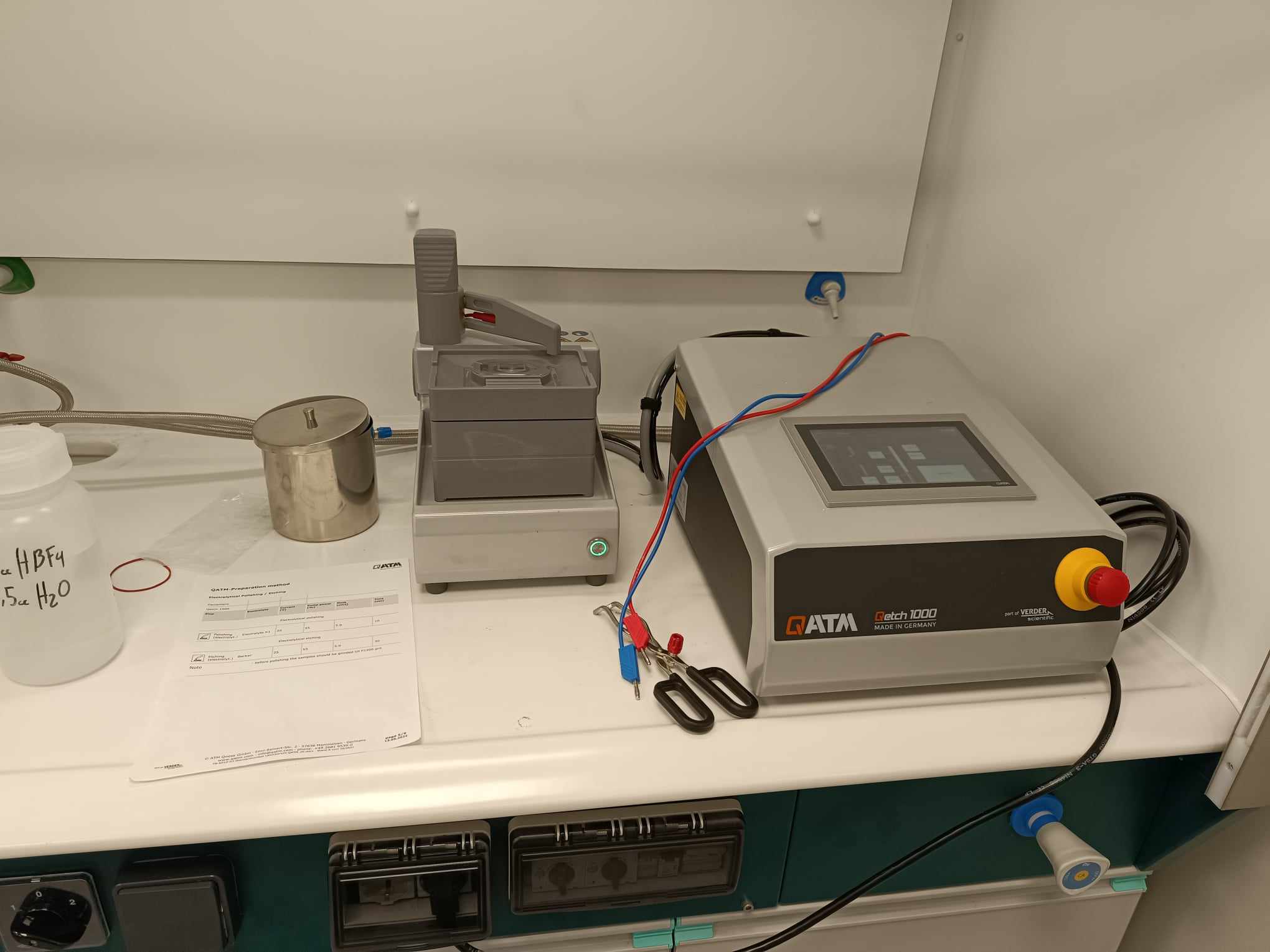

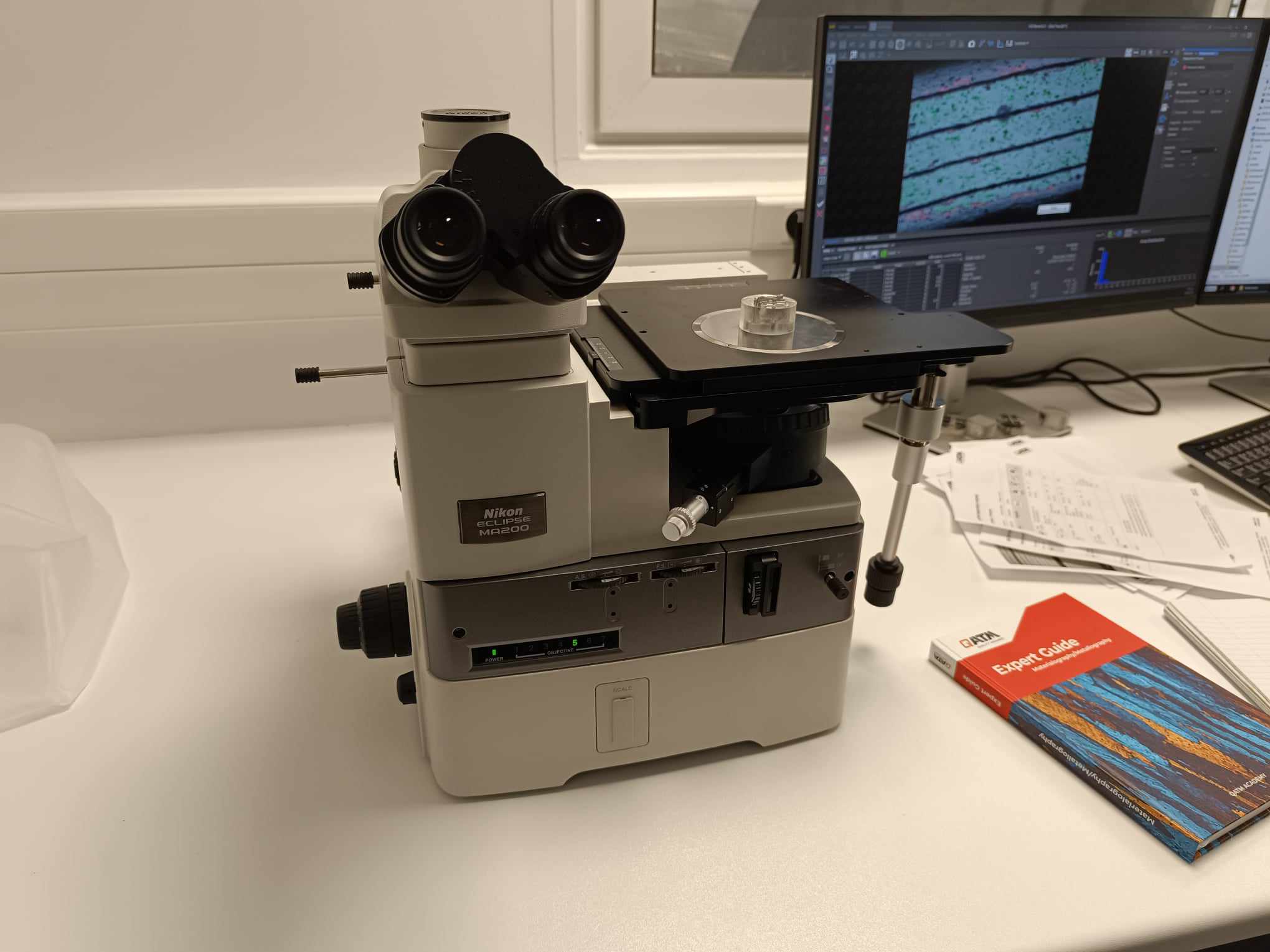

Our company has created a complete metallographic laboratory on behalf of a partner, successfully completing the installation of a fully equipped research and development lab for metallographic preparation of aluminum samples for microstructure analysis and the identification and measurement of intermetallic compounds.

Specifically, the project included systematic training of users, which took place not on dummy samples but on real samples from our partner, providing immediate and practical solutions.

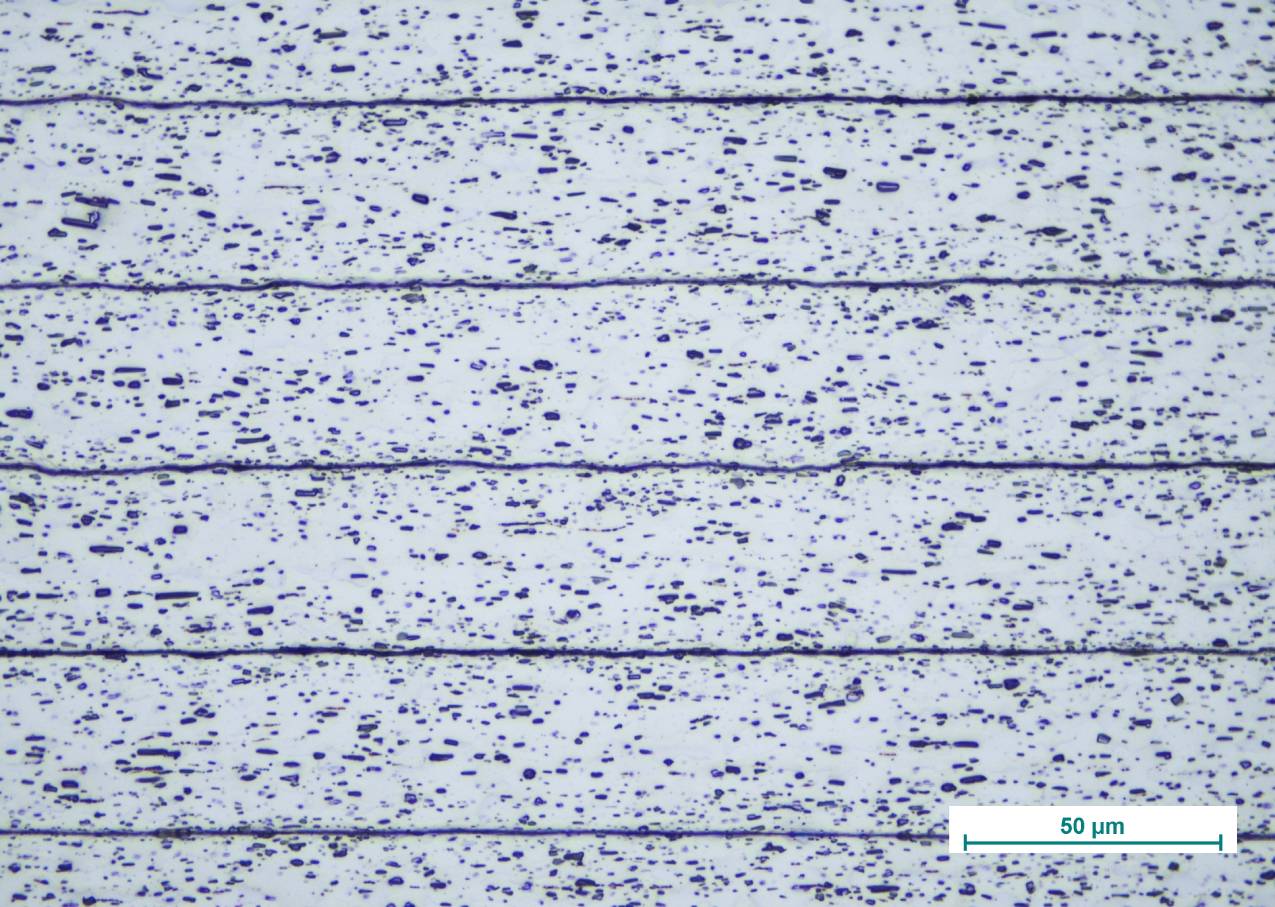

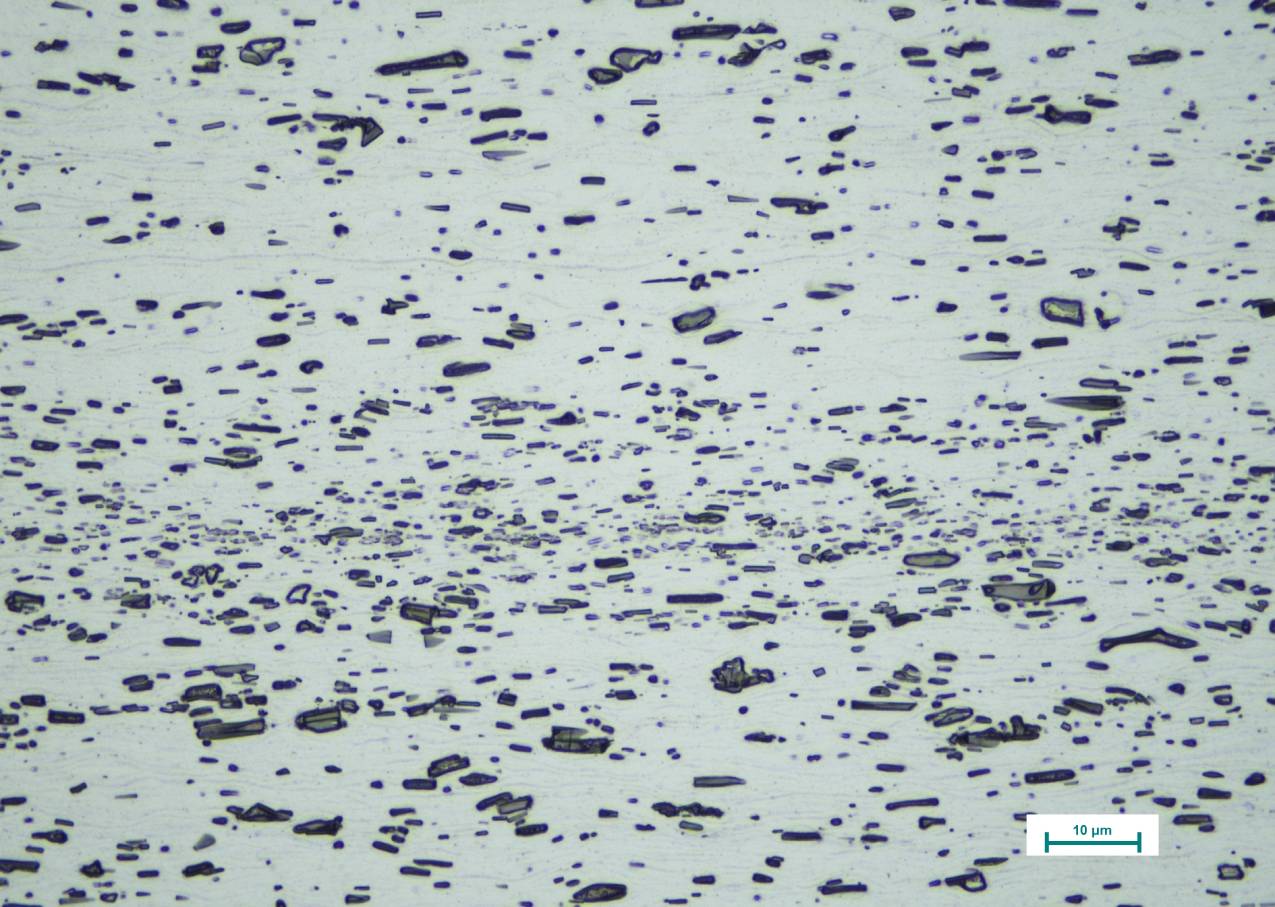

During the observation of the samples, the following high-resolution brightfield microstructure images were created using a polarizer.

Get in contact with us, share the details of your application and we will be happy to recommend the specialized equipment required to achieve the microstructure result you desire.

10, Agion Anargiron Str.

Marousi Attica, 151 24

Greece

Η Διοίκηση της Applied Laboratory & Engineering Solutions έχει καθορίσει και τεκμηριώσει την πολιτική της για την ποιότητα, βασισμένη στην εφαρμογή Συστήματος Διαχείρισης Ποιότητας κατά το διεθνές πρότυπο ISO 9001:2015 για τη δραστηριότητα της:

ΕΜΠΟΡΙΑ ΕΠΙΣΤΗΜΟΝΙΚΩΝ ΟΡΓΑΝΩΝ ΚΑΙ ΕΞΟΠΛΙΣΜΟΥ

Η Διοίκηση εξασφαλίζει ότι αυτή η Πολιτική Ποιότητας είναι κατανοητή, εφαρμόζεται και διατηρείται σε όλα τα επίπεδα.

Όραμα της Επιχείρησης είναι η αύξηση του μεριδίου της αγοράς και η ισχυροποίηση της ανταγωνιστικότητάς της προσφέροντας υψηλής ποιότητας προϊόντα.

Φιλοσοφία της Applied Laboratory & Engineering Solutions είναι:

Γενικές κατευθυντήριες οδηγίες:

Αθήνα, 12 – 09 – 2022

Η Γενική Διευθύντρια

Μαρία Λογοθέτη

The Management of Applied Laboratory & Engineering Solutions has defined and documented its quality policy, based on the implementation of a Quality Management System according to the international standard ISO 9001:2015 for its activities:

TRADE OF SCIENTIFIC INSTRUMENTS AND EQUIPMENT

Management ensures that this Quality Policy is understood, applied, and maintained at all levels.

The company’s vision is to increase its market share and strengthen its competitiveness by offering high-quality products.

The philosophy of Applied Laboratory & Engineering Solutions is:

General Guidelines:

Athens, 12 – 09 – 2022

The Director

Maria Logotheti