As a rule, the following principle is followed during cutting:

For hard materials, a cutting wheel with a soft bonding material is recommended, to ensure the quick breakage of the bonds holding the cutting/grinding media.

For medium-hard materials, a cutting wheel with medium-hard bonding material is recommended, to ensure the uniform wear of the bonds holding the cutting/grinding media.

For soft materials, a cutting wheel with a hard bonding material is recommended, to ensure the slow breakage of the bonds holding the cutting/grinding media.

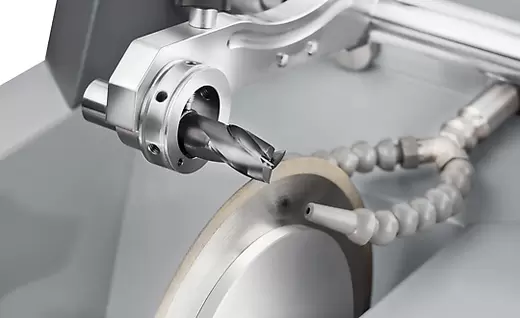

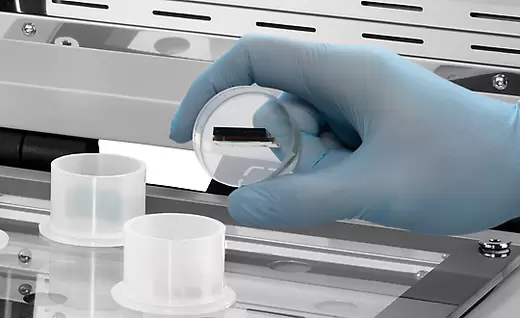

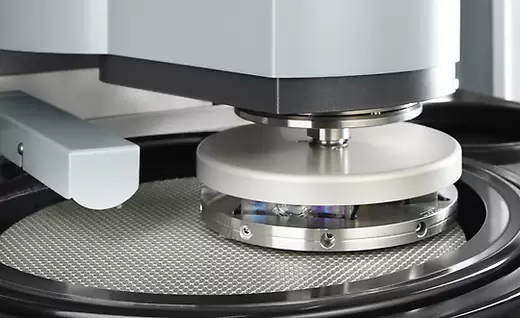

Depending on the geometry and hardness of the material, as well as the analysis techniques used, different cutting techniques and consumables should be selected. Specifically, different cutting wheels are available for metallographic sections/cuts, as well as suitable cutting fluids, coolants, and anti-corrosive fluids, additives, and antibacterial fluids suitable for the recirculation units of cutting machines.