Νowadays, the term cold mounting is generally used for all methods where no or small pressures (<5 bar) are applied. The technical requirements of cold mounting are minimal compared to the metallographic hot mounting procedure. Only a mold and the two-component resin are required. In addition to hardness and abrasion resistance, shrinkage, cure (pot life) and exothermic heat development are the main selection criteria. The process is as follows: The sample is placed in a mold and the exact weight or volume ratios of the filler materials (resin-hardener) are carefully measured. They are then mixed well and poured into the mold preferably under vacuum for optimal production of metallographic samples with good adhesion and no air bubbles. Qatm offers the following devices for cold mounting of metallographic samples.

QPREP Infiltration - Device for cold mounting under vacuum

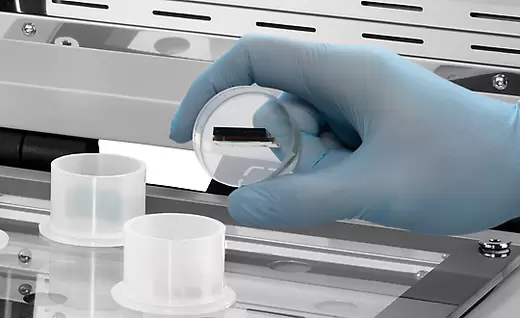

The QPREP INFILTRATION device is a filtration system for vacuum cold mounting, positioning, and hardening of metallographic samples using vacuum technology. It is recommended for epoxy resins and is ideal for cases where cold embedding of porous samples is required. In such applications, it is advisable to carry out the embedding/mounting under vacuum using a low-viscosity filling medium, such as resin. This process can be achieved through the QPREP infiltration device.

The system consists of a desiccator with mechanical dosing including a check valve, vacuum pump, tubing, and pressure gauge. Additionally, it features a rotating disc that can hold up to 8 or 9 cold embedding molds of Φ40, Φ50mm, or even smaller diameters of your choice (Φ25mm, Φ30mm). You can also place rectangular embedding molds of the required dimensions for your application. The device is delivered with 10 mixing cups for resin and hardener.

The device is suitable for embedding porous samples and offers enhanced retention for fragile/brittle samples.

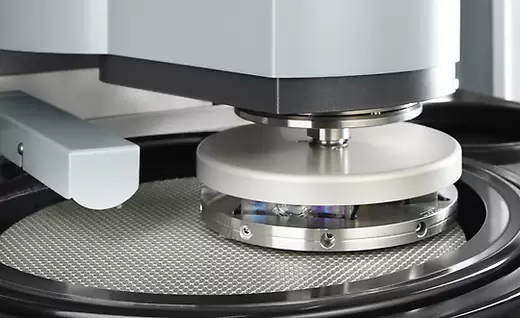

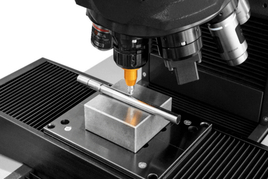

QPREP PRESSURE

Device for pressure embedding/mounting, suitable for bubble-free curing, recommended for acrylic resins. The device is designed for mounting/embedding metallographic samples under pressure, ideal for producing bubble-free samples using acrylic resins. Compressed air of approximately 6 bar is required. The system is suitable for producing transparent embedded samples using methyl methacrylate resins. The samples to be embedded harden in the pressure device under the application of positive pressure (2 - 2.5 bar), which raises the boiling point of the fixing/filling material and suppresses the formation of gas bubbles during polymerization. The QPREP PRESSURE unit is perfectly suited for this purpose.