Sample Preparation Ion Coater

(Hassle-free Compact Ion Sputter Coater)

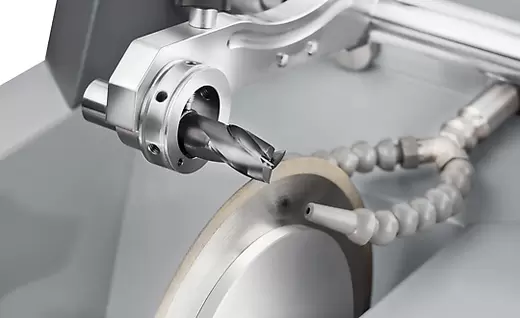

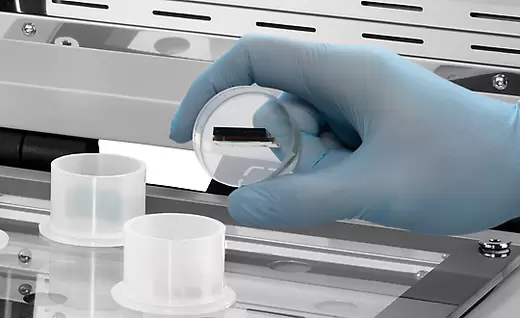

The desktop model of the sputtering coating device for preparing non-conductive samples for observation in SEM electron microscopes is a machine designed to deposit a thin metal coating (Au or Pt) on non-conductive samples in order to make their surface electrically conductive and prevent the charging effect during observation in SEM electron microscopes.

Specifications

First Name | Last Name | Countries | Capitals |

|---|---|---|---|

Vacuum Degree | 2.0 x 10-2 Torr | ||

Ion Current | 1 to 10mA (1mA/step) | ||

Target Material | Au or Pt | ||

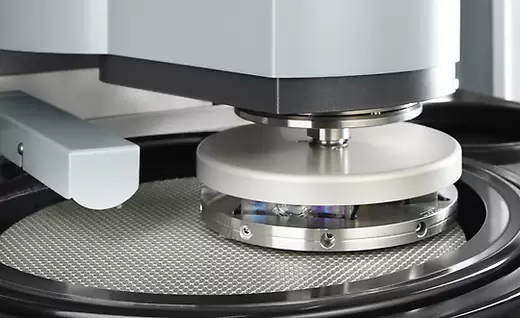

Chamber Size | Φ140mm(D) x 100mm(H) | ||

Sample Stage | Φ50mm(D) x 30mm(H) | ||

Target Size | Φ50mm(D) | ||

Sputter Time | 1 to 600sec (1sec/step) | ||

Vacuum Pump | 100L/min, Rotary Pump (Recommended) | ||

Dimension | 350(W)x 210(L) x 230(H)mm, 10kg |