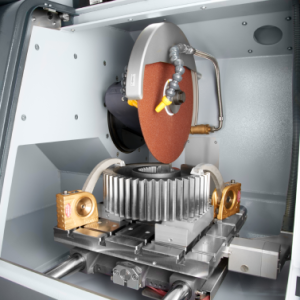

Cut-off Machine BRILLIANT 255

The universal wet abrasive cut-off machine Brillant 255 with manual travel and fine dynamic cutting allows precise, soft touch cutting with 2 axes in arbitrary directions (Y/X axis) and can be equipped with a manual Z-axis for parallel serial cuts (option). Side openings allow cutting continuous long parts in the spacious cutting chamber of this solid and powder-coated aluminium construction. Complex geometric shaped samples can be fixed securely on the T-slot table using our reliable clamping systems. The vibration reducing design of the cutting arm allows a low noise cutting process. Our approved LED cutting chamber illumination is energy saving, damage resistant and guarantees optimum illumination of the cutting chamber.

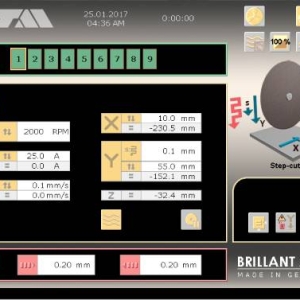

Cut-off Machine QCUT 400 A

The successful Qcut 400 A was fundamentally revised and equipped with new features for increased comfort and performance. The cutting machine presents proven quality and a wide field of application.The new Qcut 400 A, designed for cut-off wheels of 406 mm is a floor model with a large travel in X-axis of 345 mm and in Y-axis of 200 mm. The standard configuration includes adjustable rotational speed, the parallel moving wheel guard, as well as the cut detection. The machine can perform all relevant cutting modes (e.g. pulsed cut, diagonal cut) and so meeting the customer’s needs. The innovative Quick-Change System for changing the cut-off wheel makes maintenance work faster and more comfortable. A new high-power LED lamp illuminates the cutting chamber for best light conditions. The Multi-Position process (MPP) allows cutting at different positions in just one sequence. Setting and approaching of cutting positions is made easy and comfortable with the Teach-In-Function. The automatic pulsed clamping system realizes parallel cuts of variable thickness of 5 – 130 mm for samples of maximum thickness up to 20 mm. The automatic table, one of the largest in its class, provides the operator with precision, flexibility, and space for clamping issues. During work a large sliding door always guarantees safe and fast access to the cutting chamber without coolant dripping into the workspace of the operator. The large touch screen shows the intuitive control software clearly and brightly for a user-friendly operation.

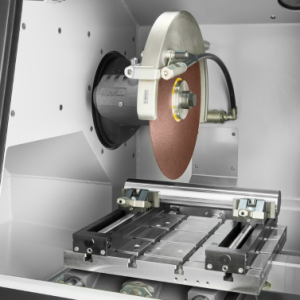

Cut-off Machine QCUT 500 A

The universal wet cut-off machine Qcut 500 A meets the highest of demands on space available and possibilities for cutting with its innovative concept for design, construction and operation. The automatic horizontal table (X-axis) and cutting wheel movement (Y-axis) can reach up to 80 mm/sec. through highly dynamic axis drives in rapid-run. Compact program sequences are easy to compile with Touch-Screen display. The parallel setting of the wheel guard during vertical cutting sequences increases the cutting capacity considerably. The large front and hinged door with safety lock enable access to the machine table with longitudinal and cross T-slots. Recirculating cooling and automatic central lubrication systems are integrated into the robust aluminum construction body of the machine.

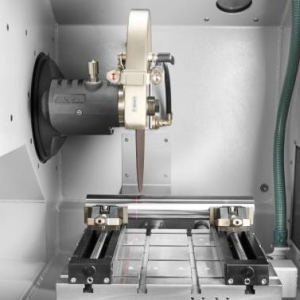

Cut-off Machine QCUT 600 A

The industrial wet cut-off machine Qcut 600 A meets the highest of demands on space available and possibilities for cutting with its innovative concept for design, construction and operation. A water-cooled 15 kW main motor is integrated into the swing arm and the automatic horizontal table (X-axis) and cutting wheel movement (Y-axis) can reach up to 80 mm/sec. through highly dynamic axis drives in rapid-run. With a totally new approach with the automatic cross-feed movement (Z-axis) through the swing arm, the cutting chamber is ideally put to use. Parallel setting of the wheel guard during vertical cutting sequences increases the cutting capacity considerably. The large front and hinged door with safety lock enable access to the machine table with longitudinal and cross T-slots. The side door allows easy and convenient change of the cut-off wheel if Z-axis is set on the hard right position. Recirculating cooling and automatic central lubrication systems are integrated into the robust welded steel construction body of the machine.

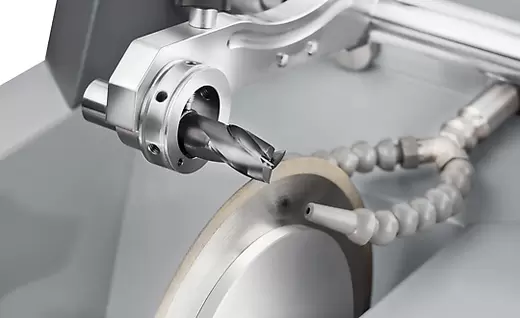

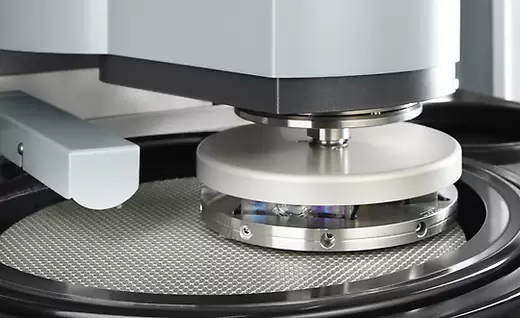

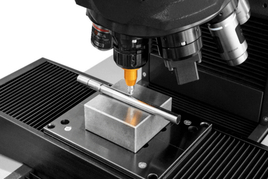

Cut-off machine QCUT 600 BOT

The Qcut 600 BOT is a fully automatic cutting robot with max. 5 axes for the use of cutting discs with a size of up to 610 mm / 24“. The Qcut 600 BOT cutting robot opens up new possibilities with its 5 axes (X-, Y-, Z-, B-, C-axis) and the generously sized machine table (Ø 600 mm) opens up new application possibilities. The automatic travel (X-axis) and cross-cut (Y-axis) reach speeds of up to 80 mm/sec thanks to its highly dynamic drives.The rotary table (B-axis) has a swivelling range of 360° and can be modularly extended with an additional rotary axis (C-axis - swivel range of combined axes: B-axis: 200° / C-axis 360°).The cut-off wheel guard is guided in parallel during the chop cut to increase the cutting capacity of the cut-off wheel. The large sliding and side door, with safety lock when the cutting disc moves, ensures the best possible access to the large machine table.Recirculation cooling and automatic central lubrication are integrated in the machine body of the robust steel construction. The Qcut 600 BOT can also be equipped with a belt filter unit as an alternative to the recirculating cooling unit.