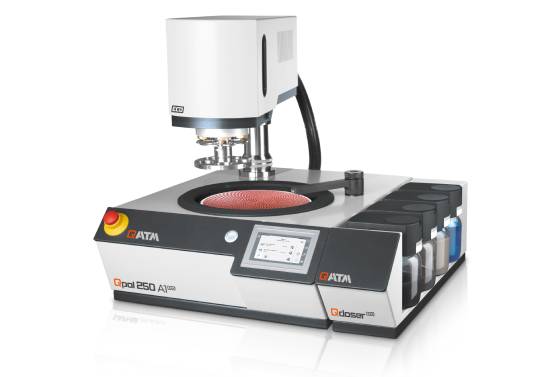

Single & Dual Wheel Grinding/Polishing Machines QPOL 250 A1-ECO & QPOL 250 A2-ECO

The QPOL 250 A1-ECO & QPOL 250 A2-ECO models are single and dual wheel grinding/polishing machines, respectively, suitable for any metallographic laboratory. They come with grinding wheels of Ø 200/250 mm and feature a user-friendly 4.3" touchscreen. The new holder for the working wheel (single-disc design) enables metallographic sample preparation without carrier disc without compromising performance. The control software allows to edit and save up to 200 preparation methods, protected by a user account management. Pressure, speed and direction of rotation (head and working disc) are adjustable. A spin cycle function (Cleaning Boost) helps to spin dry the grinding and polishing medium at 750 rpm at the end of the preparation process within 3 seconds. These robust grinding and polishing machines can be combined with the Qdoser ECO or Qdoser ONE automatic dosing system, offering maximum flexibility for sample preparation and operating convenience.

Single & Dual Wheel Grinding/Polishing Machines QPOL 300 A1-ECO+ & QPOL 300 A2-ECO+

The QPOL 300 A1-ECO+ & QPOL 300 A2-ECO+ models are single and dual wheel grinding/polishing machines, respectively, suitable for any metallographic laboratory. They come with grinding wheels of Ø 250/300 mm and feature a user-friendly 4.3" touchscreen. The new holder for the working wheel (single-disc design) enables metallographic sample preparation without carrier disc without compromising performance. The control software allows to edit and save up to 200 preparation methods, protected by a user account management. Pressure, speed and direction of rotation (head and working disc) are adjustable. A spin cycle function (Cleaning Boost) helps to spin dry the grinding and polishing medium at 750 rpm at the end of the preparation process within 3 seconds. These robust grinding and polishing machines can be combined with the Qdoser ECO or Qdoser ONE automatic dosing system, offering maximum flexibility for sample preparation and operating convenience.

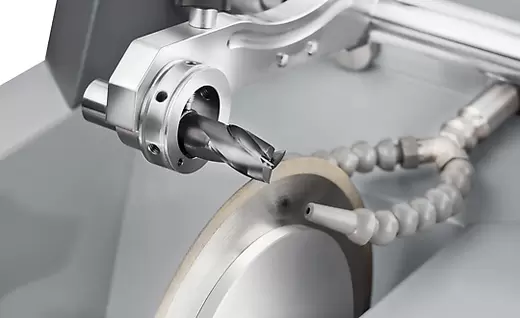

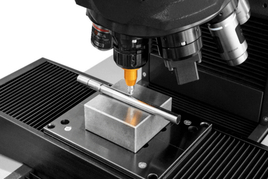

Grinding/Polishing Machines SAPHIR 550 & SAPHIR 560 WITH RUBIN 520 HEAD

The grinding/polishing machines SAPHIR 550 / RUBIN 520 & SAPHIR 560 / RUBIN 520 are modernly designed grinding machines featuring an innovative grinding and polishing head for working wheels Ø 250-300 mm. These machines come as single working wheel models (SAPHIR 550 / RUBIN 520) or dual wheel models (SAPHIR 560 / RUBIN 520) with the common feature of the automatic sample holding head RUBIN 520.

The RUBIN 520 head is equipped with an automatic protective cover, setting new standards in operational safety. It operates with both single and central pressure, features memory functionality, and offers the option for an integrated dosing system. Additionally, it has the unique capability for material removal measurement.

The height adjustment is motorized, and pneumatic clamping of the main units SAPHIR 550 & SAPHIR 560 meets the highest demands. The material removal height can be pre-set with an accuracy of 0.01 mm. The measurement of the removed material is performed automatically, and once the pre-set value is achieved, the machine automatically shuts down.

Grinding & Polishing Machine QPOL XL

High sample throughput with maximum reliability: The Qpol XL is a robust and powerful powerhouse with unique removal performance and excellent preparation results. With maximum stability of body and polishing head, this unit is part of a series of QATM floor standing polishing machines. The integrated load cell and the innovative motorized force control allow defined material removal and highest process reliability. The storage of up to 200 preparation methods is possible in the intuitive software as well as professional user management.

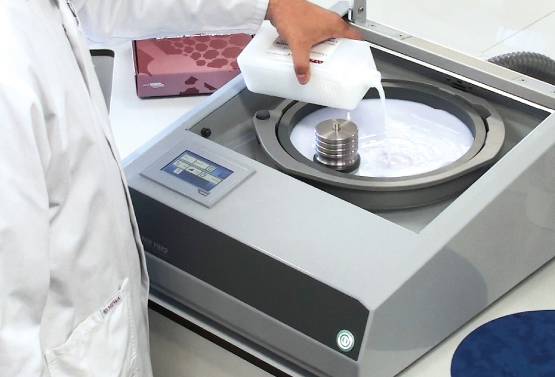

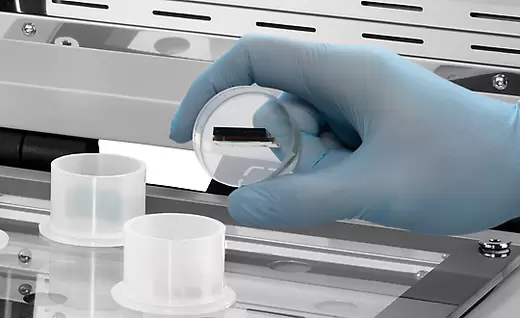

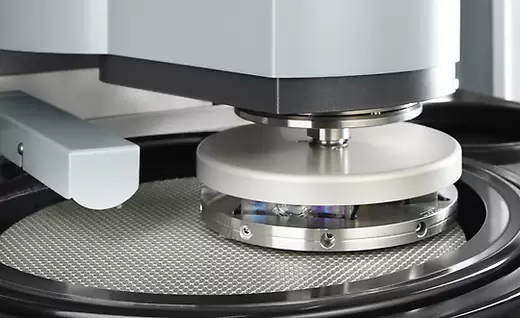

Vibratory Polisher QPOL VIBRO

The vibratory polishing device Qpol Vibro is designed for the preparation of specimen surfaces practically without deformation. This preparation method is especially suited for further characterizations like EBSD (electron backscatter diffraction), nano indentation using AFM (atomic force microscopy) or micro hardness testing. Due to the very gentle removal of material it is applicable especially for soft and ductile materials, like titanium-aluminum, pure copper and copper alloys, aluminum alloys, soft steel, and nickel-based alloys. Having a diameter of Ø=308mm, the large bowl provides sufficient space for polishing of a complete sample holder, large specimens or for the simultaneous polishing of up to 21 mounted specimens. The bowl is equipped with a double magnetic system. It allows to fix, remove and clean both the bowl or polishing cloth very quickly, without any tools or other fixings.

Polishing cloths suited for magnetic system with a diameter of 300mm or 305mm (12”) can be used.

The user interface is very intuitive and offers a lot of features supporting the operator.

For achieving best working conditions the Qpol vibro is equipped with an exhaust connection plug, which can be connected to an external exhaust air system. Based on the vibration adsorbing construction the Qpol Vibro provides a low noise operation.