Hot mounting could also be called hot biaxial pressing. It is a process in which a granulated polymeric material is softened, compressed, and cooled down sequentially. The process is carried out in a metallographic hot mounting press, designed for this application.

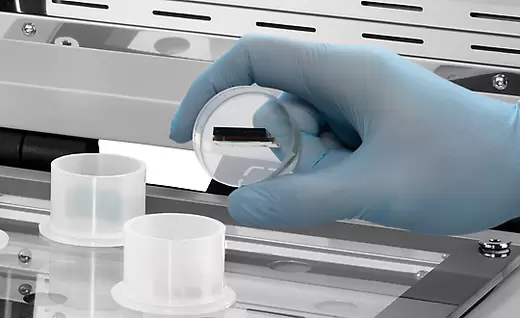

Of course, this method may only be applied on sufficiently pressure- and temperature-resistant samples with simple geometries. The process is carried out at temperatures of 150 to 200°C, while the pressure depends on the mould diameter and ranges from 100 to 300 bar. After placing the sample on the lower ram, the mounting material is added and the process started.

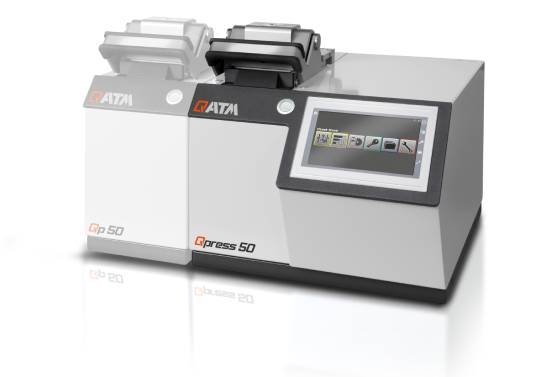

Hot Mounting Press QPRESS 50

The hot mounting press Qpress 50 is a modular machine used in metallography for the fast, simultaneous and independent mounting of different materialographic specimens. The modularity of the Qpress 50 allows adjusting the machine configuration for varying sample sizes and throughputs, depending on customer requirements. The base unit of the hot mounting press contains control interface and one mold assembly. It is available in 2 versions:

Qpress 50-2: can be equipped with one additional pressing station (total up to 2)

Qpress 50-4: can be equipped with up to three additional pressing stations (total up to 4)

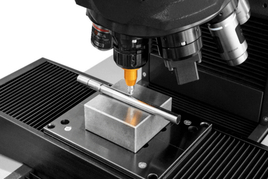

Hot Mounting Press OPAL 410

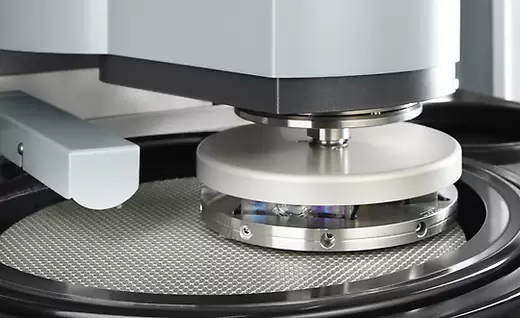

The OPAL 410 is a fully hydraulic, water cooled hot mounting press for mounting samples before polishing. The process sequence is executed automatically. Mould assemblies can be exchanged quickly and without tools. The robust aluminium construction is powder coated. With its solid construction and QATM hydraulic system, the operating noise of the hot mounting press is minimized. Our comprehensive selection of mould assemblies from Ø 25.2-40 mm and different pressure methods enable optimum mounting of your sample. Two mounts can be produced simultaneously with the use of a spacer.