Manual Grinding & Polishing Machines QPOL 250 M1 & QPOL 250 M2

The Qpol 250 M1 & Qpol 250 M2 models are manual grinding and polishing machines with single and dual wheels respectively, for working wheels Ø 200/250mm. The start/stop button with an illuminated status indicator and the rotary switch with a scale and integrated boost button allow for a highly aesthetic, smooth, and high-quality operation. The integrated fast spin cleaning function (Cleaning Boost) helps with the quick drying of the grinding and polishing medium at 750 rpm at the end of the preparation process within 3 seconds, after which the device shuts off. The particularly strong, speed-controlled drive makes these models suitable for all steps of metallographic preparation and for all materials. Additionally, the working disc can operate with both clockwise and counterclockwise rotation. The impact-resistant plastic bowl, the powder-coated aluminium housing and the high-quality components inside the device are the basis for smooth running and best preparation results. The devices can be combined with the manual dosing system Qdoser GO or Qdoser ONE to add a high degree of flexibility for metallographic sample preparation as well as ease of operation.

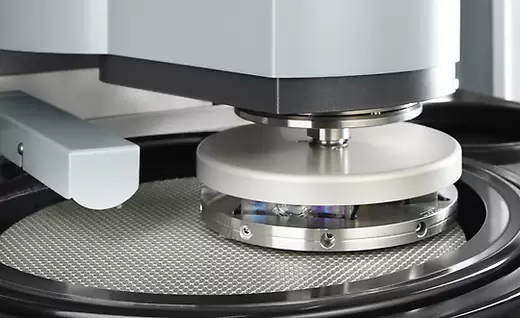

Manual Grinding and Polishing Machines QPOL 300 M1 & QPOL 300 M2

The Qpol 300 M1 & Qpol 300 M2 models are manual grinding and polishing machines with single and dual wheels respectively for working wheels Ø 250/300 mm. On their ergonomically integrated touch screen, all grinding/polishing process parameters, as well as convenient functions for manual preparation, are clearly displayed and can be easily adjusted at any time. Additionally, all process parameters can be saved as preparation methods. The adjustable timer and the torque display for visualizing the current grinding pressure enable comfortable and reproducible manual preparation steps. The water valve is automatically switched on/off when the preparation starts or ends.

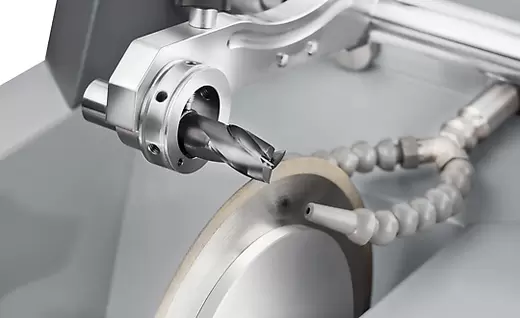

Grinding & Polishing Head QPOL GO

The Qpol GO grinding and polishing head enables the perfect introduction to automatic sample preparation and can be combined with the single and twin wheel grinding and polishing machines Qpol 250 M1 / 2 and Qpol 300 M1 / 2.The established technology, simple construction and the intuitive operating concept allow simple and fast preparation steps. The grinding/polishing pressure (single pressure) and the preparation time can be continuously adjusted using the corresponding rotary control directly on the grinding and polishing head. The working area of the polishing head is easily accessible and visible thanks to LED illumination and the particularly slim design.The robust device can be combined with a dosing dropper bottle Qdoser ONE that can be screwed onto the polishing head or the Qdoser ECO dosing system and offers maximum flexibility for sample preparation and operating convenience. With the appropriate preparation, Qpol GO can be retrofitted on the manual grinding machines.

Automatic dosing system QDOSER GO

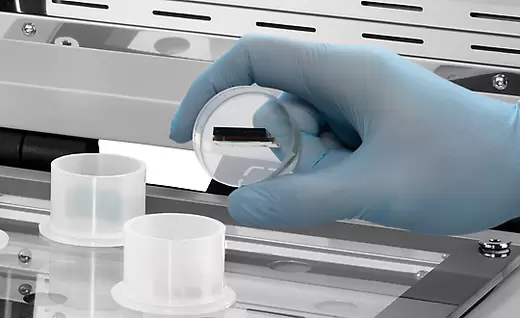

The automatic dosing system QDOSER GO is universally suitable for use with all manual grinders. Four 500 ml glass bottles with screw caps hold 3 x suspension and 1 x lubricant or 4 x Dia-Complete and can be filled via a separate lid. They are easily removed for cleaning.The holder for dosing nozzles for manual dosage may be freely positioned on the machine. The dosage interval can be variably set via the control panel. The backflushing function keeps the hoses clean.

Dosing Units Qdoser ECO / Qdoser ECO+

The Qdoser ECO and Qdoser ECO+ fully automatic dosing units speed up grinding and polishing processes in the materialographic laboratory and are designed for use with the automatic grinding machines of the Qpol 250/300 A series. 4 screwable 500 ml glass bottles can hold diamond suspensions, lubricant or final polishing suspensions and can be filled through a separate lid, even during operation. They are quickly removed for easy cleaning.The dosing nozzles are easily attached to the grinding and polishing head. The dosing is controlled fully automatically by the software of the Qpol devices. A backflushing function keeps the hoses clean.

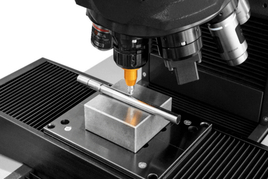

Portable Grinding & Polishing Machine QPOL 30

Qpol 30 is a portable grinding and polishing device designed for manual operation in the field. It is suitable for applications where replica techniques are required, as it is the tool that prepares the surfaces to be examined before the microstructure is captured using a replica.