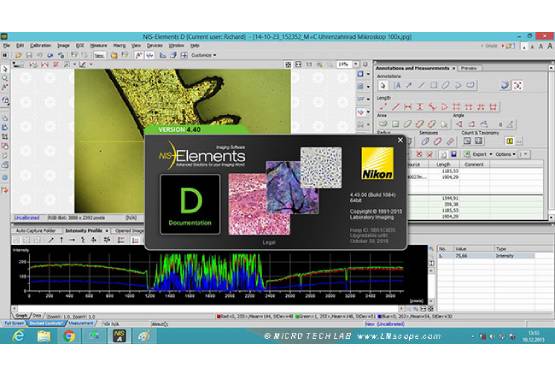

Nikon NIS-Elements Imaging Software

NIS-Elements is a fully featured imaging software solution for microscopy. Fast, powerful imaging processing tools are available, such as for creating a mosaic or compound image from many separate images, e.g. following a long micro-crack on a sample surface from start to finish. For industrial or academia applications, Nikon offers NIS-Elements AR (Advanced Research), BR (Basic Research), D (Documentation), and L (for a tablet PC).

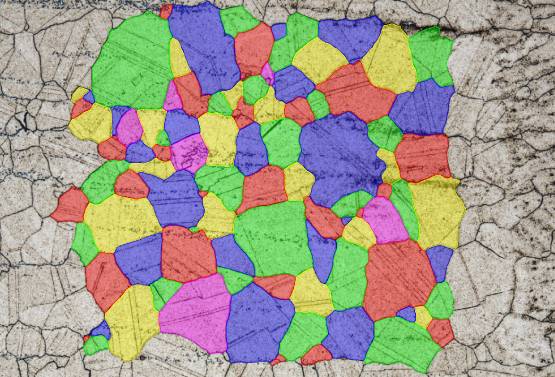

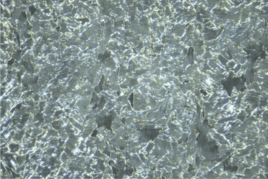

Artificial Intelligence (AI) software for grain size detection in Aluminum/Bronze/Austenitic and Ferritic single-phase structures.

AI and machine learning make automatic grain segmentation and distinction an effortless process for the user. Traditional manual thresholding for grain segmentation can be challenging and tedious, even for experienced operators. With AI, this method can often become obsolete.

Key features

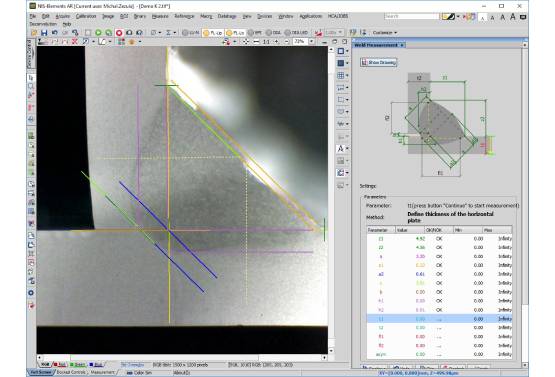

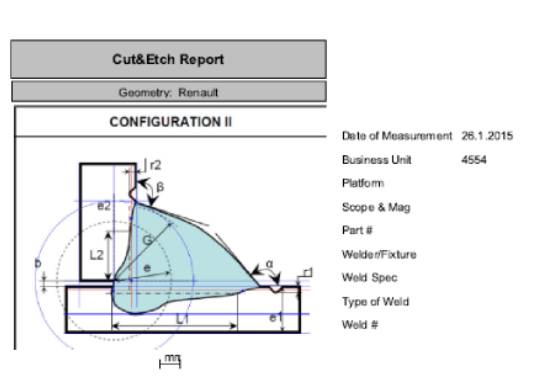

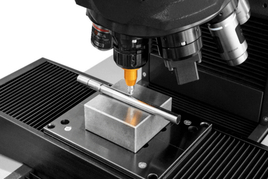

Measurement Sequencer Software for Weld Seam Measurement

This is an additional software plugin module for weld measurement applications, featuring an automated sequence definition for measurements (e.g., predefined ISO 5187 Fillet & Butt welds and custom-defined recipes). It offers guided measurement functionality, ideal for reducing user errors. This practically eliminates the possibility of missed steps during measurement procedures and ensures that no measurements are omitted from your reports.

With a built-in guidance system for designing measurements, users can follow schematic instructions and tips for convenient, easy, and accurate measurements. Simply point and click to place your measurements. Additionally, the software provides a text-to-speech guide for further assistance.

The predefined measurement sequence definitions include:

These options offer a wide range of automated measurements, ensuring that various types of welds and hardness tests can be performed accurately and efficiently.

Report Generation (Reports)

These features ensure that detailed and customizable reports can be produced for documentation and analysis purposes.

Parameter and Progress Monitoring Over Time

Image Organizer

Building and Customizing Your Own Measurement Definitions

This feature allows users to tailor their measurement processes to specific needs, providing flexibility in defining custom metrics, calculations, and limits while ensuring ease of use and repeatability.